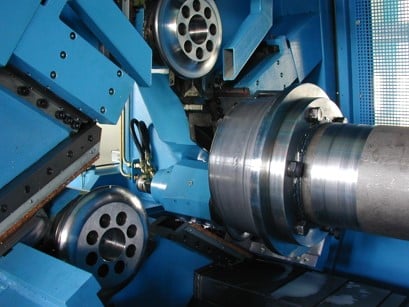

Flow forming is a metal-forming technique for manufacturing tubular components. A tubular preform is formed over a mandrel by rollers applying pressure. The material is rotated and is stressed in a particular zone above the yield point so that it flows in an axial direction.

The advantage of flow forming is to achieve a reduction in wall thickness. The final state is attained by pure compressive loading. The pressure applied to the material first of all serves to increase the work piece’s strength and also lengthens the material. The result is an extended work piece with enhanced material properties, a higher load-bearing capacity and a longer service life than components produced by metal cutting processes.

AST produces cylindrical tubes of any wall thickness. Learn about our flow formed products for the aerospace industry, and the alternative energy industry.