- One-piece Combustion Chambers and Nozzles

- Seamless, Type 3 Liners, Cylinders, and Tank Components

- Rotary Forged Wheel Blanks

Looking for a metal spinning specialist, supplier or factory? Let us help solve your biggest project challenges.

- Cylindrical, Conical, Parabolic, and Spherical Shapes from Forged preforms made from Aluminum, Copper, Titanium, Stainless, and other alloys

Our Products

Rocket Engine Components

- Rocket nozzles, combustion chambers, and other rocket components.

- AST has completed challenging metal spinning projects in complex shapes using aluminum, copper, titanium, stainless, and other alloys for our space and aerospace customers.

Pressure Vessel Liners and Tank Components

- Type 1 vessels, Type 3 liners, tubes, cylinders, and other tank components for space systems.

- AST has extensive experience in manufacturing pressure vessels for high pressure applications.

- We welcome the opportunity to manufacture your design specifications.

Manufacturing Technologies

Forgings

Unmatched Material Efficiency

- 4 state-of-the-art CNC rotary forging presses with near net forging results

- Reduction in tooling setup times for higher spindle utilization rates

- Largest rotary forging press can forge parts with a diameter of 40”

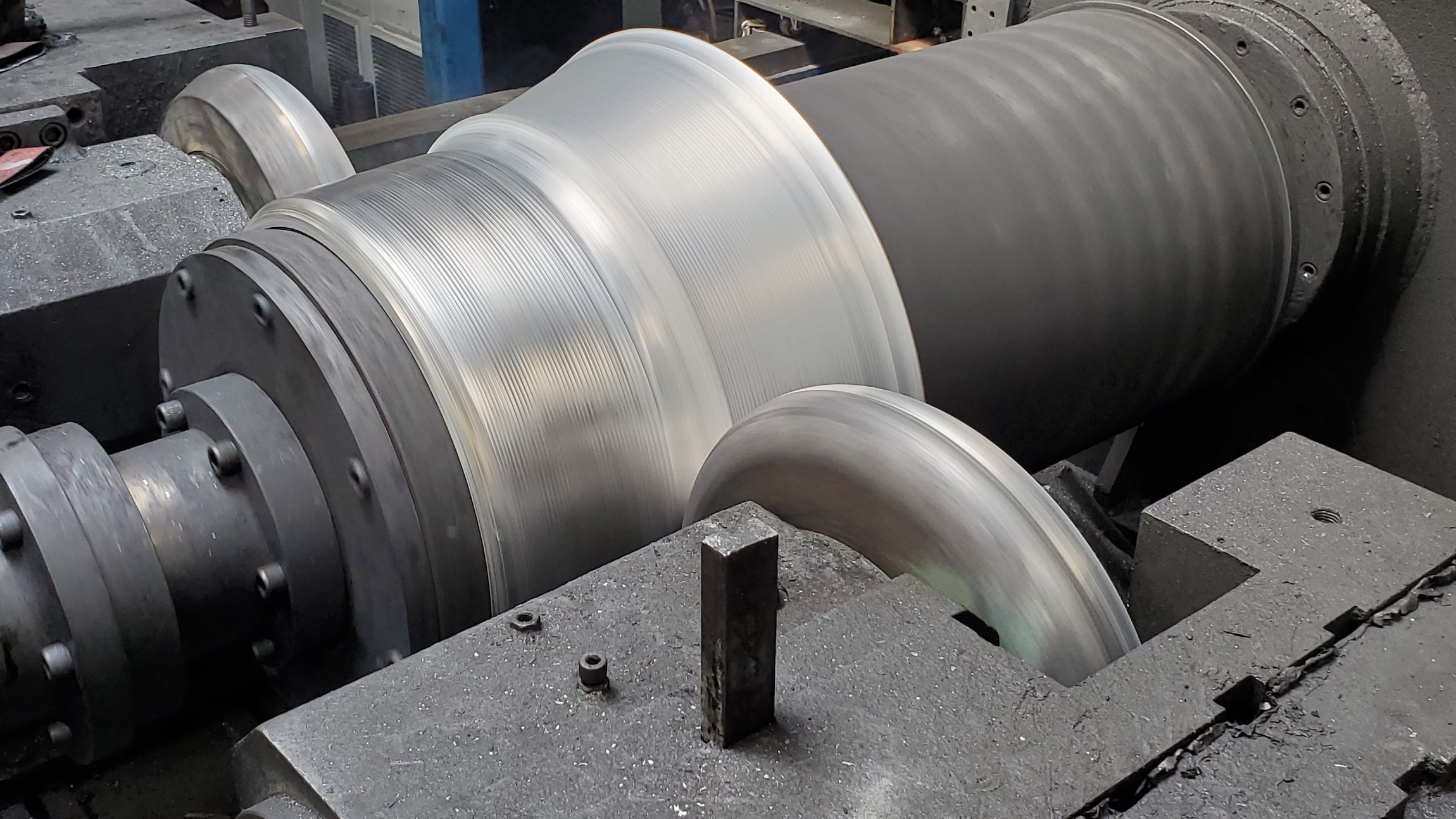

Spin/Flow Forming

Advanced Metal Forming Process

- Advanced metal forming processes designed to manufacture complex cylindrical, conical, and spherical shapes from forged preforms

- Multiple CNC controlled rollers mechanically work material over tools, creating a near net shape on the outside and inside diameter

- 7 spin/flow forming machines, creating a wide variety of rotationally symmetric shapes with a high degree of material efficiency

- Largest machines with 65 tons per axis creates large diameter tubes and nozzles for high profile space applications, oversized military wheels up to 27” diameter or 30” diameter truck wheels

- Automated robotic arm machine loading and unloading for spinning process enables high efficiency and cost effectiveness for large volume orders

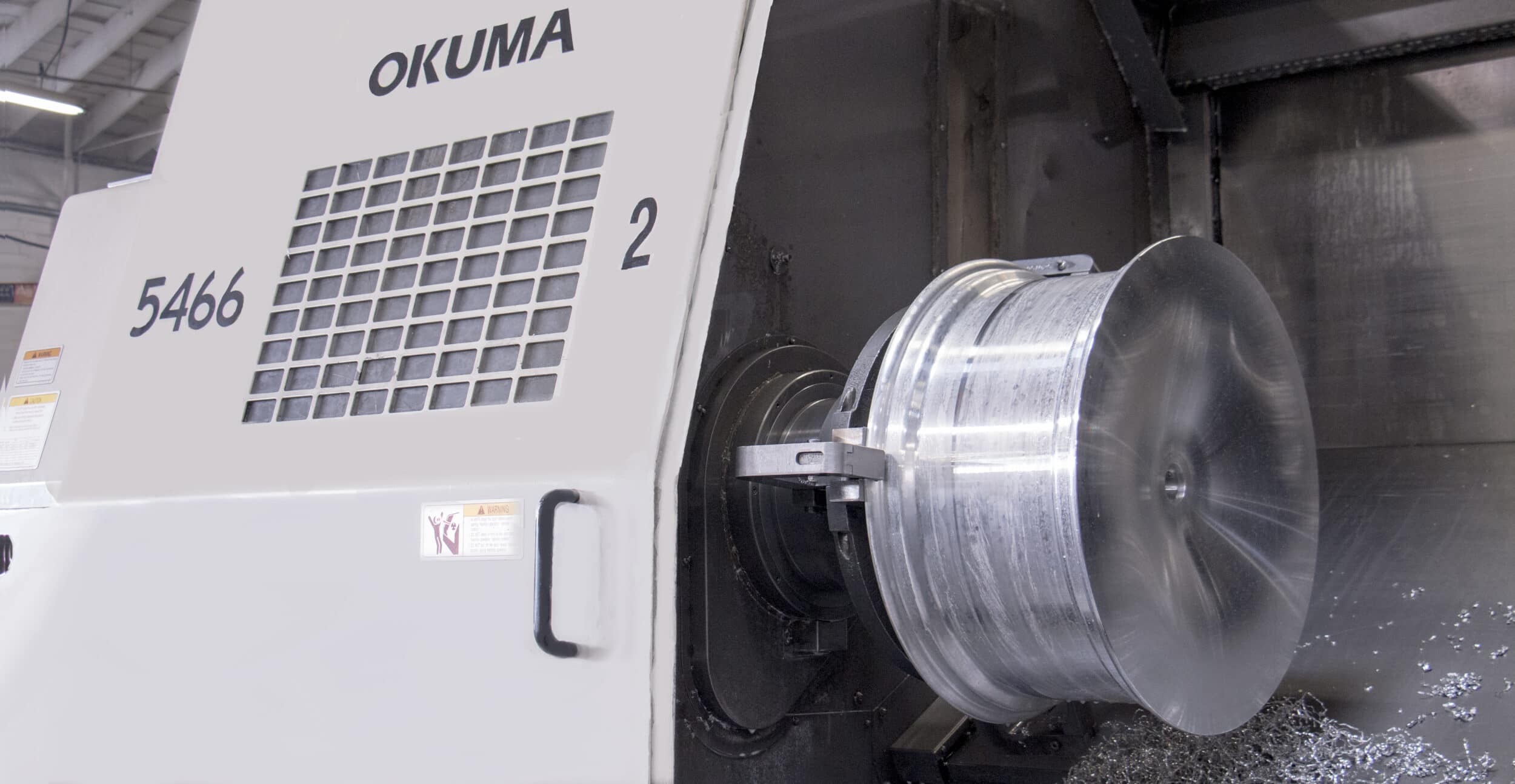

Machining

CNC Machining

- AST has both a conventional and CNC machine shop with over 45 machines for lathe turning and milling

- The machine shop has a large line-up of machines with a swing of over 40” diameter

- Strategically organized to serve multiple product segments, allowing for quick setups between projects

- Elaborate library of programs with proven simulations, part number grouped tooling kits

- Highly skilled staff of manufacturing engineers and programmers

Quality Assurance

Heat Treat

Certified and Surveyed Systems

- 2 in-house heat treat systems

- Continuous belt furnace

- Drop bottom furnace

- Both systems certified and surveyed systems support most aluminum alloys

- Continuously monitored for temperature uniformity and process control

- All product is run through a rigorous post heat treat process which consistently monitors hardness data and samples of mechanical properties

Testing & Monitoring

Committed to Safely & Efficiently Delivering Quality

- AST has a robust quality assurance process, auditing and monitoring all manufacturing processes

- Receival of raw materials, first article inspections, final inspection prior to shipping to customers

- All processes are based on detailed engineering drawings and control plans with predefined in-process inspection sheets

- State-of-the-art laser inspection instruments are used for inspection and quality assurance

- Metallurgist on staff to inspect metallurgical details such as grain structure and mechanical properties

Tooling

Fabricated In-House

- Metalforming relies on tooling to control how material moves from a starting shape to a deliverable/li>

- All tooling used for forging and spin/flow forming is fabricated in-house, enabling cost control and production schedule efficiencies

- AST uses common tooling on numerous components of the same diameter and style, reducing the amount of dedicated tooling needed and leading to shorter lead times, more product variations, and a better value for our customers